任务4 验货作业

Task Four Inspection Operation

任务导入 Lead-in

拣货组宋组长:孙组长,今天的待拣货物已经全部拣选完毕,请安排验货组验货吧。

验货组孙组长:好的宋组长,我马上组织验货。

验货组孙组长:小张,今天的验货由你来完成吧,你去发货暂存区跟拣货组交接一下。

验货组小张:好的组长,我马上过去。

验货组孙组长:验货的时候一定要仔细核对,发现有拣选错误,一定要及时上报,并做好记录。

验货组小张:组长请放心。

验货组孙组长:好,去忙吧。

Leader Song of Picking Team: Mr. Sun, all the goods to be picked today have been done, please arrange for the inspection team to inspect the goods.

Leader Sun of Inspection Team: Okay, Mr. Song, I will organize the inspection immediately.

Leader Sun of Inspection Team: Xiao Zhang, you are in charge of today's inspection. Please go to the delivery temporary storage area to connect with the picking team.

Member Zhang of Inspection Team: Okay, I'll go over right away.

Leader Sun of Inspection Team: When inspecting the goods, we must check them carefully, and if we find that there are picking errors, we must report them in time and make a record.

Member Zhang of Inspection Team: Mr. Sun, please rest assured.

Leader Sun of Inspection Team: Okay, let's get started.

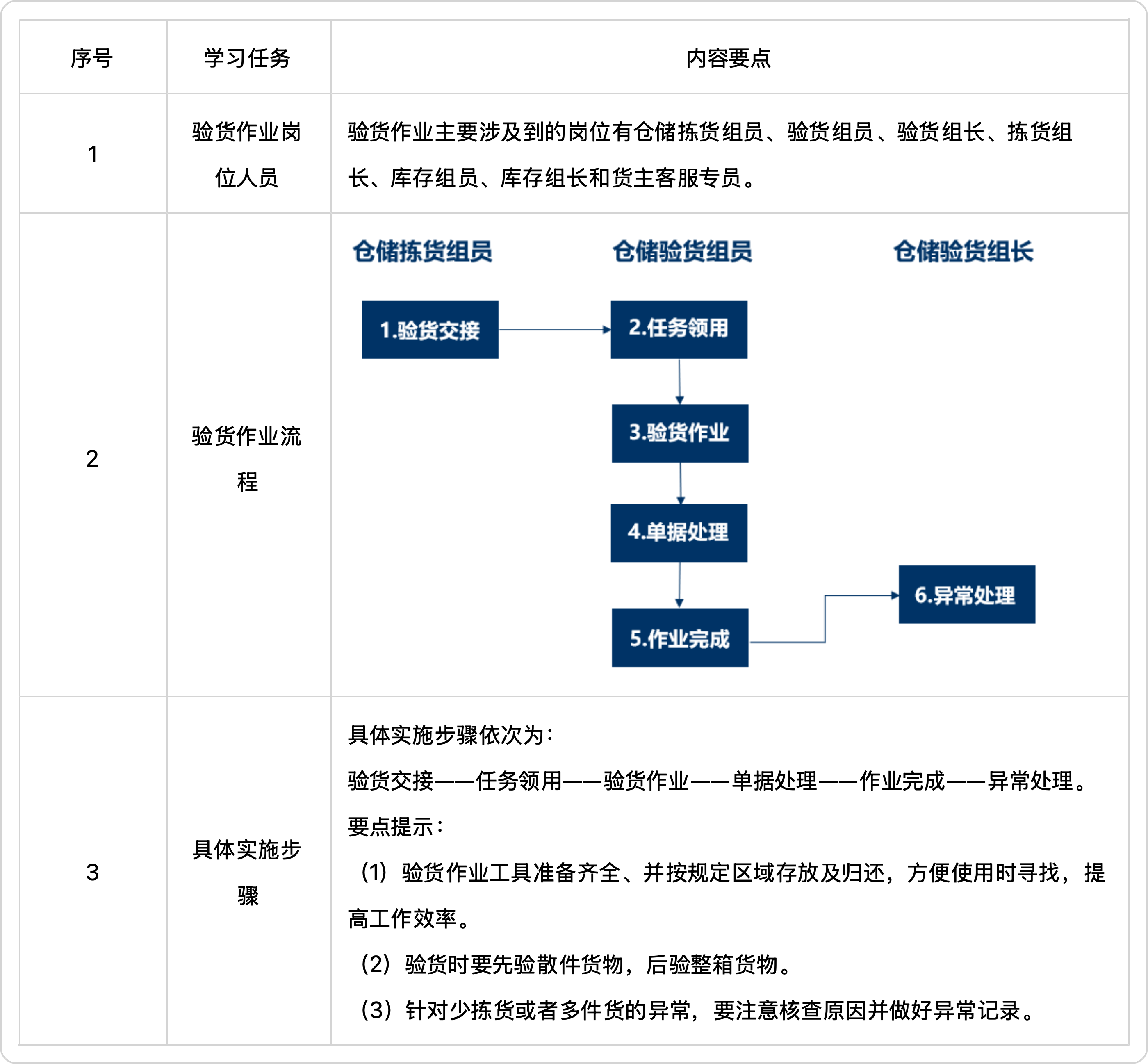

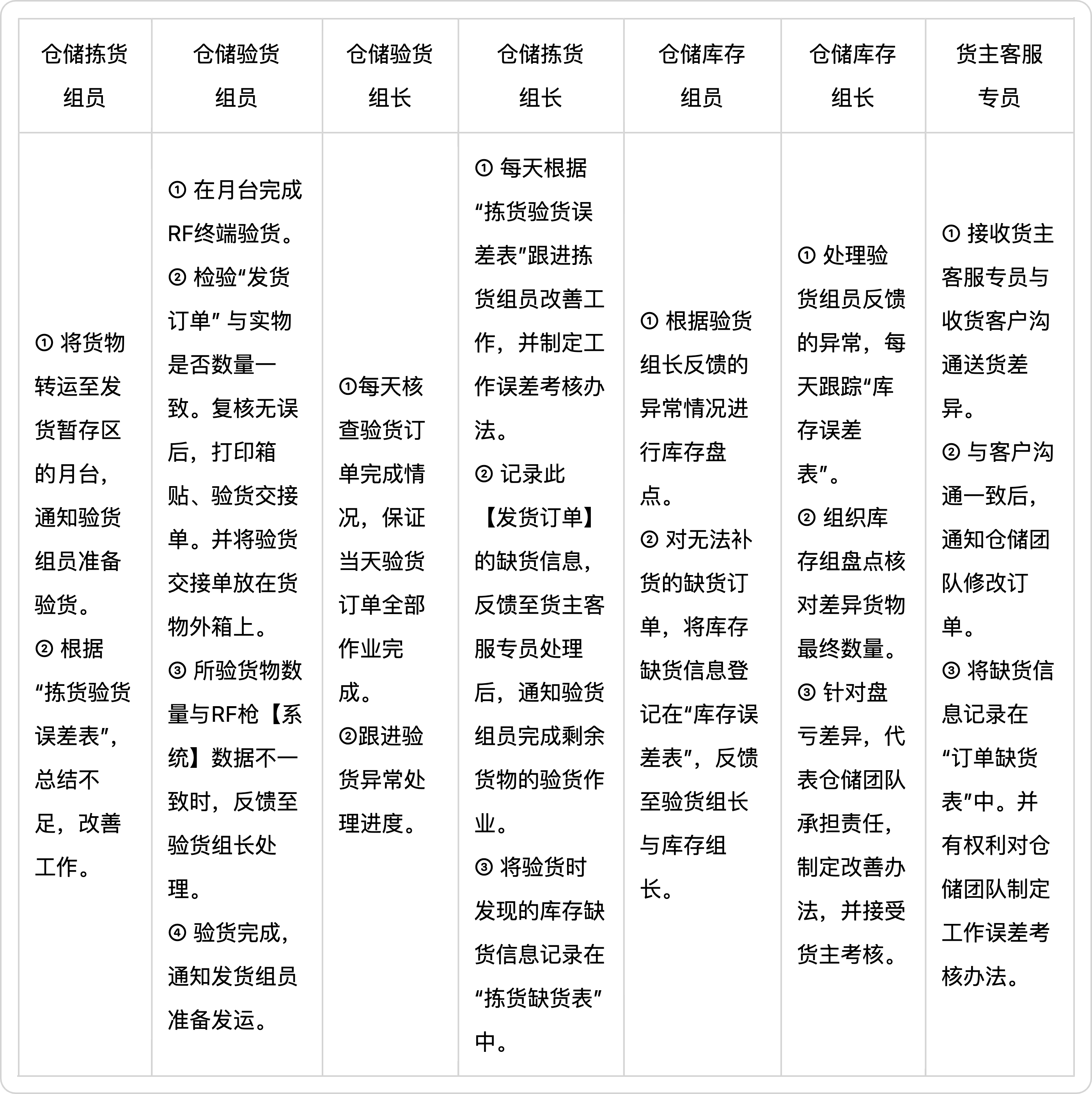

验货岗位人员及其职责 Inspection Personnel and Their Responsibilities

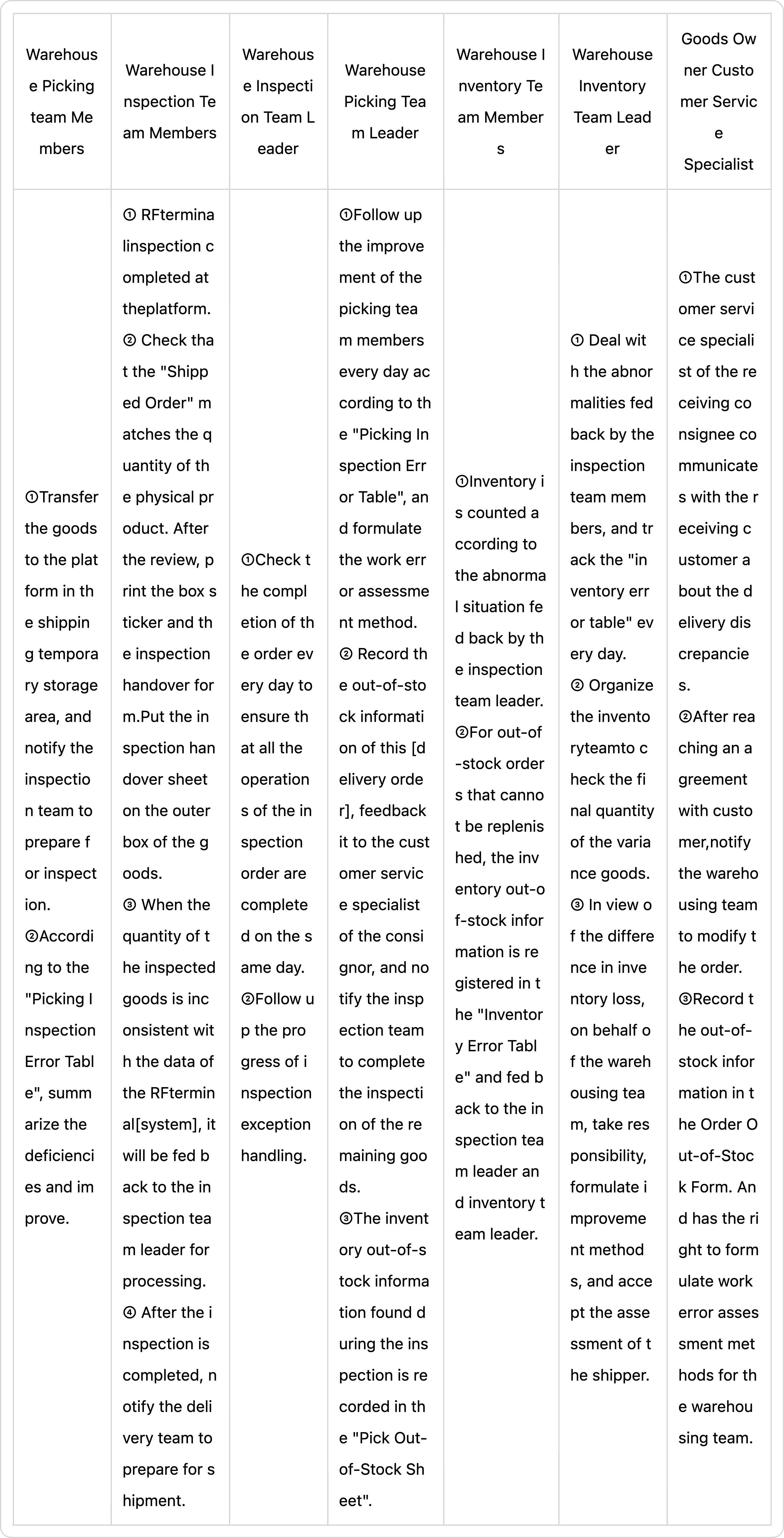

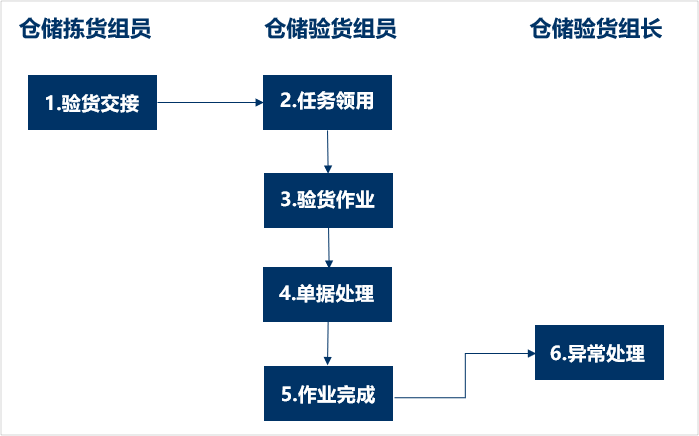

验货作业流程 Inspection Operation Process

具体实施步骤 Specific Implementation Steps

验货交接

拣货组员将货物转运至发货暂存区的空闲月台处,通知验货组员准备验货。

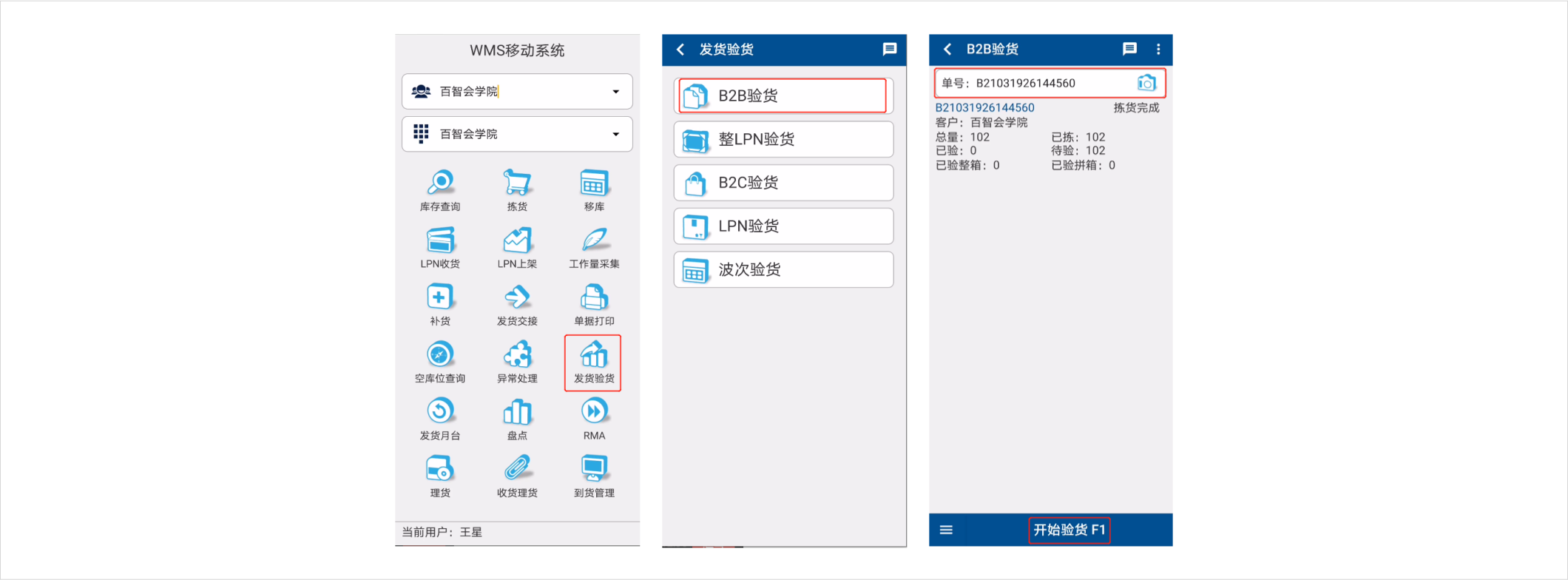

任务领用

验货组员到达有待验货物的月台处,使用RF枪开始验货:在首页点击【发货验货】,选择对应的验货类别,然后扫描分组标签(图3.4.2)上的【SO单号】对应的条码,获取订单信息,准备开始验货。

Inspection and handover

The picking team member transfers the goods to the free platform in the shipping staging area and notifies the inspection team members to prepare for inspection.

Task requisition

The inspection team member arrives at the platform of the goods to be inspected and uses the RF terminal to start the inspection: click [Delivery Inspection] on the Home, select the corresponding inspection category, and then scan the barcode corresponding to the [SO Tracking Number] on the grouping label (Figure 3.4.2) to obtain the order information and prepare to start the inspection.

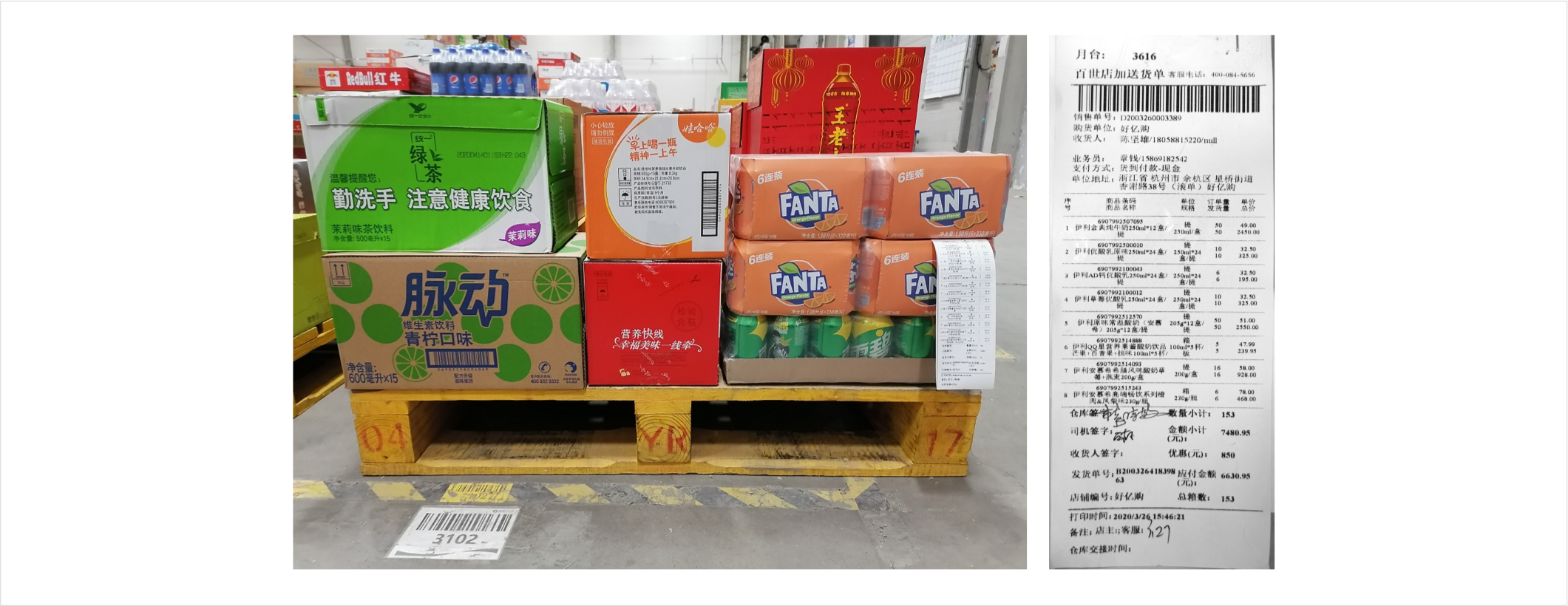

验货作业

根据货物包装情况,选择相应的验货方式(验货方式有整箱和散件两种,验货时应该优先验散件货物,散件验货完成后再切换至整箱货物),逐一扫描商品条码,直至所有待验货物全部验货完成(图3.4.3)。

Inspection operation

According to the packaging of the goods, select the corresponding inspection method (there are two kinds of inspection methods: FCL and bulk goods, and the inspection should give priority to the inspection of bulk goods, and then switch to the whole box of goods after the inspection of bulk goods is completed), scan the barcode of the goods one by one, until all the goods to be inspected are inspected. (Figure 3.4.3)

散件货物在验货完成后,需要摆放整齐,用胶带打十字型封箱,并按照封箱顺序由低到高摆放。

After the inspection of the bulk goods is completed, place them neatly, seal them with tape, and place them from low to high in accordance with the sealing order.

单据处理

验货完成后,验货组员取下分组标签,在【WMS】中打印“箱贴”和“验货交接单”。“箱贴”需要贴在对应散件箱子的固定位置(正面左下角或者侧面右上角)(图3.4.5)。

Document handling

After the inspection is completed, the inspection team member takes off the group label and prints the "box sticker" and "inspection handover form" in [WMS]. The "box sticker" needs to be affixed in the fixed position of the corresponding loose box (the bottom left corner of the front or the top right corner of the side). (Figure 3.4.5)

验货组员复核“验货交接单”与实物箱数是否一致。复核无误后,将“验货交接单”压放在托盘货物固定位置处(图3.4.6)。

The inspection team members check whether the "inspection handover order" is consistent with the number of physical boxes. After the review is finished, the "inspection handover form" is pressed at the fixed position of the pallet goods. (Figure 3.4.6)

作业完成

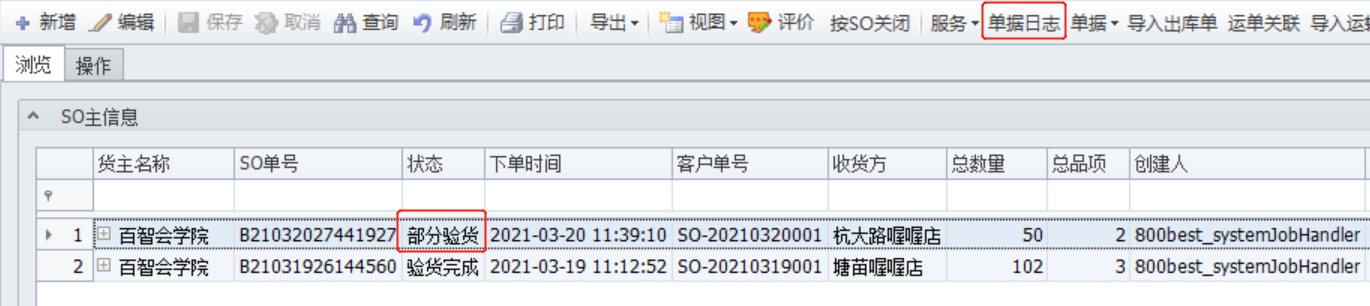

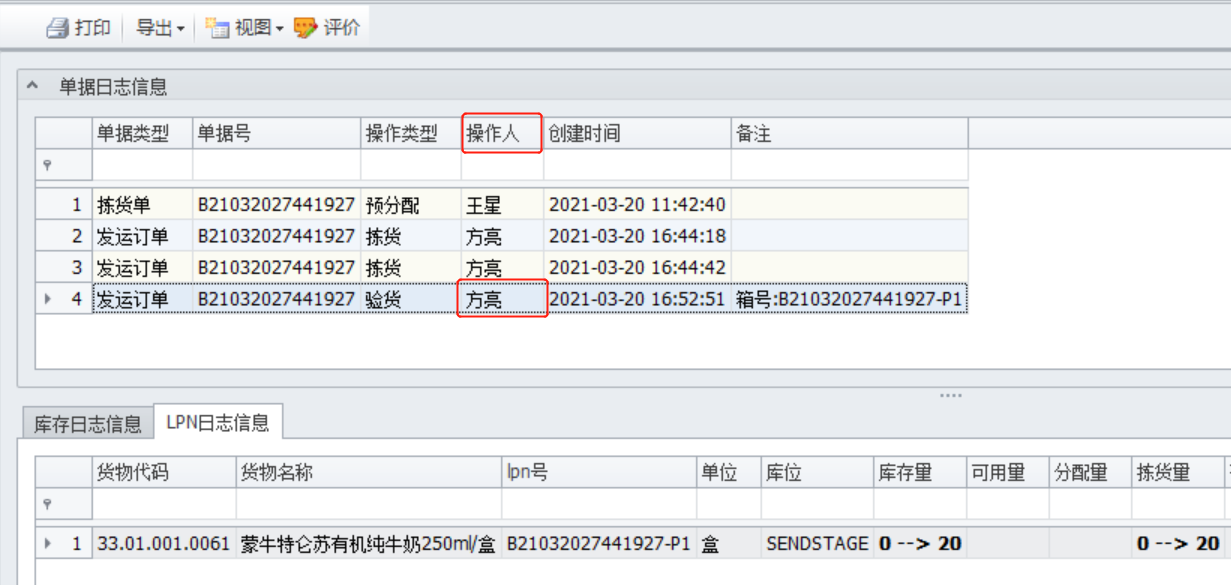

验货组员完成验货后,验货组长核查当天发货订单的验货情况,确认全部验货完成后通知发货组员准备发运。若出现部分验货情况(如因货物缺少导致)(图3.4.7),需要查看对应单据的拣货量与验货量,如两者一致,应视为验货完成;若不一致,则需要查询验货环节操作人,并跟进操作人完成验货(图3.4.8)。

Operation completion

After the inspection team member completes the inspection, the inspection team leader checks the inspection of the order delivered on the same day, and confirms that all the inspection is completed and notifies the delivery team member to prepare for shipment. If there is a partial inspection situation (such as due to the lack of goods) (Figure 3.4.7), it is necessary to check the picking quantity and inspection quantity of the corresponding documents, if the two are consistent, the inspection should be deemed to be completed, if not, it is necessary to inquire about the operator of the inspection link and follow up the operator to complete the inspection (Figure 3.4.8).

异常处理

少拣货

验货过程中发现拣货组员少拣货,验货组员将少拣货物数量告知库存组长,库存组长将情况反馈至系统组员,找到与“分组标签”对应的拣货工单,查看所缺货物的拣货库位。

①有库存时,库存组补拣所缺货物后,交给验货组员完成验货。同时将拣货人信息登记至“拣货验货误差表”中,反馈至拣货组长处理。

②所缺货物没有库存,无法补拣的,将库存缺货信息登记在“库存误差表”,并反馈至验货组长。验货组长将订单缺货信息反馈至货主客服专员处理。货主客服专员负责与收货客户沟通送货差异,避免因少量缺货而取消全部订单。并将缺货信息记录在“订单缺货表”中。

多拣货

验货过程中发现拣货组员多拣货货。验货组员将多拣货物退回拣选区,交由库存组长将多拣货物退回原库位,并将拣货人信息登记至“拣货验货误差表”中,反馈至拣货组长处理。如果拣选区货物依次盘点后,未找到缺货的库位,该货物应视为盘盈。库存组长将盘盈信息登记在“库存误差表”。

Exception handling

Less picking

If the picking team member picks less goods during the inspection process, the inspection team member will inform the inventory team leader of the number of less picked goods, and the inventory team leader will feed back the situation to the system team members, find the picking work order corresponding to the "group label", and check the inventory location of the missing goods.

① When there is enough inventory, the inventory team will make up for the missing goods and hand them over to the inspection team members to complete the inspection. At the same time, the picker's information is registered in the "Picking Inspection Error Table" and fed back to the picking team leader for handling.

② If the missing goods are not in stock and cannot be picked, the inventory shortage information shall be registered in the "Inventory Error Table" and fed back to the inspection team leader. The inspection team leader will feedback the order out-of-stock information to the customer service specialist of the consignor for handling. The shipper's customer service specialist is responsible for communicating with the customer who received the goods about the delivery discrepancy and avoiding the cancellation of all orders due to a small number of out-of-stocks. And record the out-of-stock information in the "Order Out-of-stock Form".

Extra-picking

If the picking team members picked extra goods during the inspection process, the inspection team member will return the multi-picked goods to the picking area, and the inventory team leader will return the multi-picked goods to the original storage location, and register the picker's information in the "Picking Inspection Error Table" and feedback to the picking team leader for processing. If the goods in the picking area are counted sequentially and no out-of-stock location is found, the goods are defined as inventory profit. The inventory team leader registers the profit and profit information in the "Inventory Error Table".

专业核心词汇 Vocabulary

发货验货 shipment inspection

封箱 sealing

箱贴 box stickers

验货交接单 inspection handover order

学习拓展 Further Reading

百世企业散件打包规定

1.选择与散件体积最贴近的打包箱尺寸,确保装箱后箱内空隙最小。

2.对于体积小易丢失、数量较多的货物需进行独立包装;易破损、漏液等容易污染其他货物的,也需进行独立包装。可在验货时将同一货物的散件清点核对后用包装膜缠绕包裹。

3.日化品和食品需要分开包装。禁止易污染的生活用品与食品类商品混放在一起,会带来串味等交叉污染。

4.液体类货物必须竖直放于箱内,禁止倒置、平躺放置。

5.易碎货物需要单独包装。如与箱内与其他货物混放,应放在最上层。必须在箱体外部明显位置进行标记,在交接时提醒司机轻拿轻放。

6.重货、大货应放在箱内底部,轻货、小货放在箱内上部。遵守重不压轻,大不压小的原则。

BEST Bulk Goods Packaging Regulations

1.Select the size of the packing box that is closest to the volume of the parts to ensure that the gap in the box is minimal after packing.

2.For goods that are small in size and easy to lose, and large quantities need to be packed independently; If it is easy to be damaged, leaking and other goods that are easy to contaminate, it is also necessary to pack them independently. The parts of the same goods can be counted and checked during the inspection, and then wrapped with packaging film.

3.Daily chemicals and food need to be packaged separately. It is forbidden to mix daily necessities that are easily contaminated with food products, as cross-contamination will lead to cross-contamination such as odor transfer.

4.Liquid goods must be placed vertically in the box, and it is forbidden to place them upside down or lying down.

5.Fragile goods need to be packed separately. If it is mixed with other goods in the box, it should be placed on the top layer. It must be marked in a conspicuous position on the outside of the box to remind the driver to handle it with care when handing over.

6.Heavy goods and large goods should be placed at the bottom of the box, and light goods and small goods should be placed in the upper part of the box. Abide by the principle of “Heavy goods cannot hold down light goods and big ones cannot hold down small ones.”

知识巩固 Consolidation

填空题

上图3.4.10中需要验货的商品数量是( ),已验的商品数量是( ),待验的商品数量为( ),验货是否完成( )。

答案:102 102 0 是选择题

验货完成后,取下分组标签,开始打印箱贴、验货交接单等单据。其中箱贴是需要贴在( )的固定位置上。

A.托盘

B.所有货品

C.散件箱子

D.整箱货品

答案:C判断题

验货方式有散件和整箱两种。验货时要优先进行整箱验货。( )

答案:×技能训练

训练任务 完成验货操作

【训练目标】

熟悉验货作业工作流程,并能够按照验货标准流程规范实施。

【训练内容】

在完成拣货作业的基础上完成如下验货任务:

1.领取验货任务。

2.验货组员按照订单明细,开始验货操作。

3.验货组员验货无误后,进行单据交接。

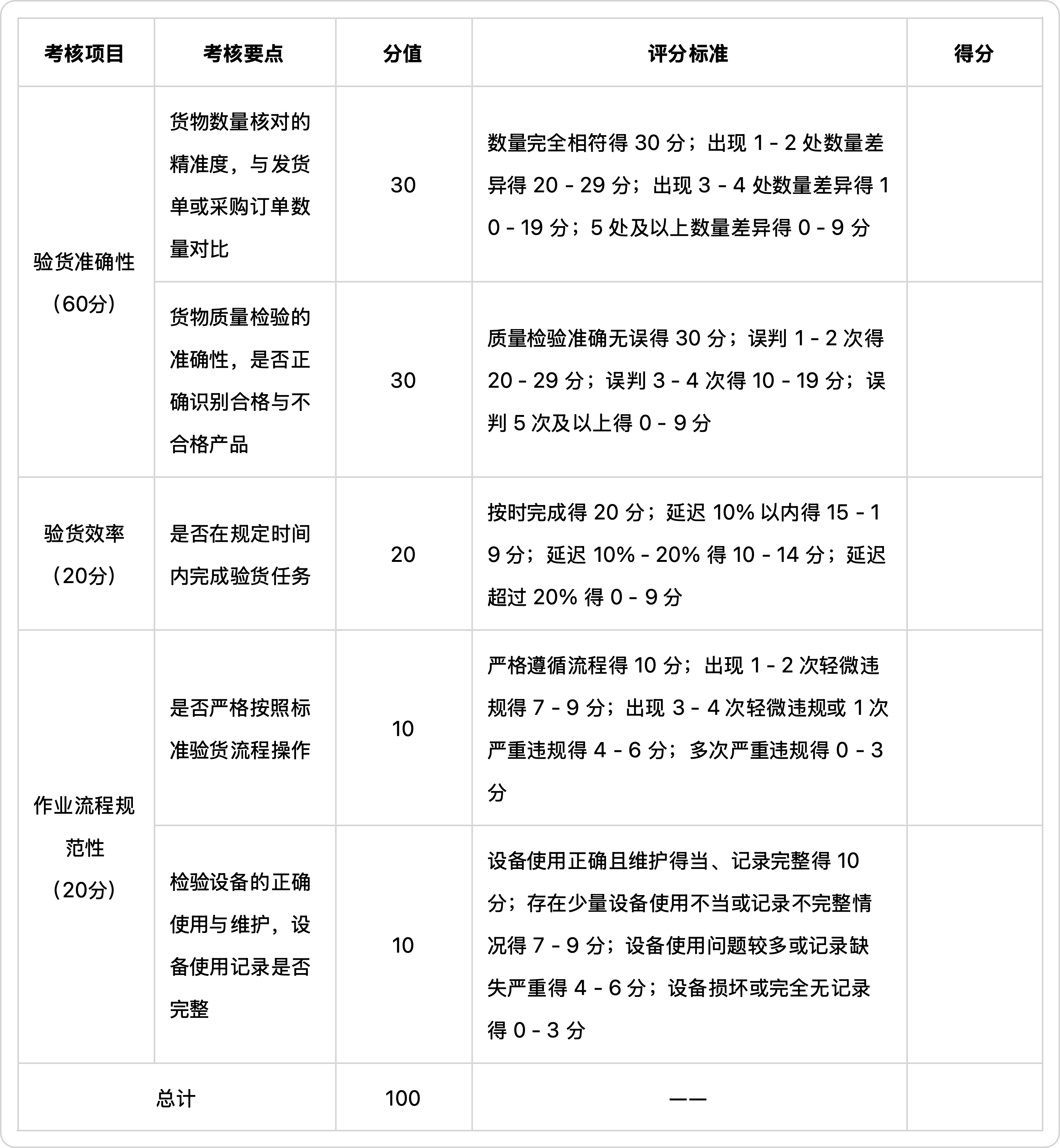

【考核评价】

操作日期: 年 月 日

微课

验货作业

验货作业认知

工作视频

验货作业-1工具准备及任务交接

验货作业-2系统操作

验货作业-3异常处理

课件

任务小结

本节课学习任务要点梳理如表3.4.3所示: